User Manual - 4 Way Circular 'Cycloid' Polarization Antenna

ANTENNA

Incorrect antenna can cause RF burns and levels of RF exposure above the recommended limits for personnel

Incorrect antenna can cause RF burns and levels of RF exposure above the recommended limits for personnel

Under NO CIRCUMSTANCES should the antenna be mounted and used at ground level or within a few meters of personnel.

A tuned antenna with the 50 ohm coaxial cable should be used. This should give a return loss ideally of 16dB (SWR 1.4) or better at the operating frequency. The RF plug should be PL259 (UHF) or N type, depending which is fitted to the FM transmitter.

Ensure that all antenna connections are sound, this is important as poor connections and soldered joints can cause RF burns to personnel, severe noise to the transmission and excessive RF bandwidth. Do NOT connect the antenna to the transmitter yet.

Ideally the antenna for this transmitter should be ideally mounted 20 meters high and clear of any surrounding objects to get maximum range and more importantly to reduce risk of radio frequency radiation to personnel. When mounted at 20 meters in height off ground and using 3000 watts of transmitter power, power flux density measurements made at ground level directly under the antennas described above show less than 1 W/m2. Several European countries use a value for the power flux density of 10 W/m2 as a basis for considering whether or not an area is safe. The issue of radio frequency radiation limits is a contentious one and work in this field is continuing worldwide.

| Qty | Antenna Parts |

| 4 | A. Cycloid (square) main dipole with RF connector and Teflon support |

| 8 | B. Vertical radiator with: ◼ 1 x M6 x 50mm screw ◼ 1 x M6 washer ◼ 1 x M6 spring washer ◼ 1 x 25mm diameter tube ◼ 1 x 19mm diameter tube ◼ 1 x 25mm hose clamp |

| 4 | C. Joining clamps with: ◼ 4 x M6 x 40mm screw ◼ 8 x M6 washers ◼ 4 x M6 spring washers ◼ 4 x M6 nuts |

| 4 | D. Boom extension |

| 4 | E. Tuning arm / gamma match bars with: ◼ 1 x M4 Allen head screw ◼ 2 x M4 washers ◼ 1 x M4 nut ◼ 2 x M6 x 40mm screws ◼ 4 x M6 washers ◼ 2 x M6 spring washers ◼ 2 x M6 nuts ◼ 1 x 10mm aluminum sleeve |

| Qty | Antenna Parts |

| 4 | F. Mast fixing clamps with: ◼ 2 x U-bolts ◼ 4 x M8 washers ◼ 4 x M8 spring washers ◼ 4 x M8 nuts ◼ 4 x M6 x 50mm screws ◼ 8 x M6 washers ◼ 4 x M6 spring washers ◼ 4 x M6 nuts |

| 3 | G. Splitter box with N-Type or DIN-716 connectors |

| 4 | H. Cable 90 degree connector LMR400 + 63cm RG11 marked GREEN |

| 2 | I. Cable marked BLUE LMR400 + 63cm RG11 marked GREEN |

TOOLS YOU WILL NEED

◼ PVC or better Self Amalgamating Tape

◼ Metric Tape Measure

◼ 7mm, 10mm, 13mm Spanner

◼ Allen key 3mm

ASSEMBLY - CYCLOID DIPOLES

Assemble the four cycloid dipoles exactly as shown in the image. Make sure the spring washer and plain washer are used together, next to one and other, and tightened, this will prevent the screws working loose in the wind.

For best performance, all the pieces marked with '1' should go with each other, then '2', '3' and '4'. This is the way and order they were tested at our factory.

| MHz | Tuning Arm (E) | L cm |

|---|---|---|

| 88 | LO | 44 |

| 93 | LO | 39 |

| 98 | LO | 34 |

| 98 | HI | 33 |

| 103 | HI | 29 |

| 108 | HI | 25 |

Select from the table the frequency that is the nearest match to your frequency and the position of the Tuning Arm (E) and the length L cm.

Using M6 x 40mm Screws, two plain washers, a spring washer and a nut tighten the Tuning Arm (E) into the LO or Hi position. Loosen the hose clamps on both Vertical Radiators (B) and adjust the length of both as shown in the image to L cm, then re-tighten the hose clamps so the tubes cannot move.

ASSEMBLY - BOOM EXTENDER

Take (A) the main cycloid and join it to (D) the boom extension using (C) joining clamps and the four M6 screws and washers. Make sure the spring washer and plain washer are used together, next to one and other, and tightened, this will prevent the screws working loose in the wind.

The image shows the cable (H) with the 90 degree connector to the cycloid antenna. In total there are four cables (H) each with 90 degree connectors. Connect these four cables to the four cycloid antennas as shown in the image.

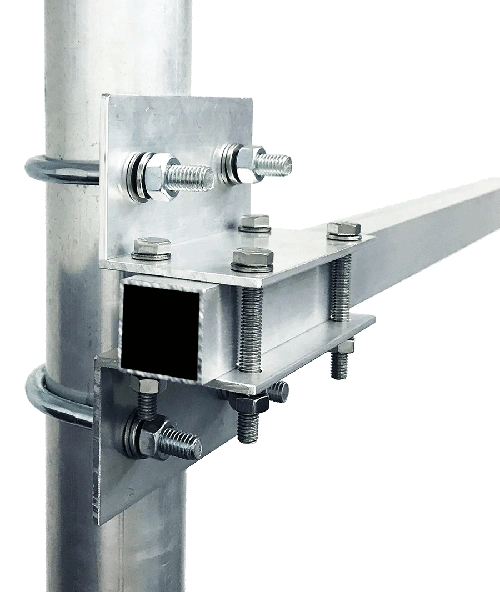

ASSEMBLY - MAST CLAMP

Using the parts marked (F) (Mast Clamps) assemble the mast clamp as shown in this photo. Make sure the spring washer and plain washer are used together, next to one and other, and tightened, this will prevent the screws working loose in the wind.

STACKING THE ANTENNAS

1. Mount the cycloid dipoles to the mast using the clamps provided in this order:

ANT.1 at the top

ANT.2 next down

ANT.3 next down

ANT.4 at the bottom.

It is also important the dimensions on the diagram are followed as closely as possible, all cycloid dipoles must be directly above each other for the system to work properly and give the full tuned bandwidth of +/- 2.8 MHz (SWR 1.5).

2. Mount the three splitter boxes using the tie wraps provided to the mast as shown in the diagram in this order:

BOX.1 between ANT.1 and ANT.2

BOX.2 between ANT.2 and ANT.3

BOX.3 between ANT.3 and ANT.4

The connectors on the splitter box should be facing down. This is because the body of the splitter box shelters, not fully, but a little, the connections from rain and water

3. Connect the main feeder cable from the transmitter to the CENTER connector of BOX.2.

4. Connect the four cables marked in GREEN from ANT.1 ANT.2 ANT.3 and ANT.4 to the outer connectors of BOX.1 and BOX.3

5. Using the two remaining (I) BLUE/GREEN cables, connect the GREEN ends to the outer connectors of BOX.2. Then connect the BLUE ends to the centre connectors of BOX.1 and BOX.3

IT'S VERY IMPORTANT THAT THIS COLOUR CODE IS FOLLOWED EXACTLY OR THE ANTENNA WILL NOT WORK

6. Wrap PVC or Self Amalgamating tape tightly around and all over the plugs on the Splitter Box to waterproof them.

7. Securely fix the cables using PVC tape or large cable ties to the mast as shown in the diagram opposite. Make sure the cables are not going to flap around in the wind.

8. Make sure that all fixings are tight and are not going to work loose over time with wind.

INSTALLTION NEAR POWER LINES

Following is a list of precautions to follow when installing the antenna if placement of antenna and cables is anywhere near power lines.

- Erect antenna on side of house or building as far away as possible from the power line.

- Avoid crossing antenna cables under electrical power lines.

- Do not attach antennas to towers, poles or similar structures carrying electrical power lines.

- If you are not experienced in installation of antennas, have experienced persons assist you.

- During installation, tie off antenna with rope so if it falls it can be diverted away from power lines.

- Avoid fastening antennas, especially self-supporting types, to old chimneys or to any chimney not designed to take such stress. Forces created by a strong wind may be sufficient to topple both chimney and antenna.

- Make sure antennas have been properly grounded and provided with other necessary lightning protection.

| Gain | 3.8dBi / 1.7dBi at 98MHz |

| Freq Range | 87.5 to 108 MHz (Factory Tuned) |

| Bandwidth | 2.8 MHz |

| SWR | 1.5 max |

| Max Power | 800W / 3000W |

| Construction | Aluminium / Teflon / Resin / Stainless Steel |

| Connector | N Female / DIN 7-16 |

| Input | 50 ohm unbalanced |

| Polarization | Circular |

| Vertical Beamwidth | 15 Degrees |

| Weight | 12 Kg |

EM COMPATIBILITY

When writing this manual there was no EU directive regarding the EMC (Electro Magnetic Compatibility) of Band II VHF broadcast antennas, however in our view there are some potential EMC compatibility issues that need to be addressed when installing this antenna system. On completion of the antenna installation check;

1. All the cables entering the connectors are tight and properly crimped or soldered

2. All the connectors are screwed in tight and sound.

3. PVC insulation tape and/or self amalgamating tape are wrapped around all the connectors to stop water entering the connector and the inside of the body of the cable.

If any cables are loose or there are bad connections this can cause some non-linear resistance, diode action or some small arcing. When this happens it creates EMC disturbance (arcing and crackling sound) across a wide frequency spectrum.

MAINTENANCE

Because antennas are passive devices maintenance requirements are low, however don’t accept low as being none existent, some periodic inspections are required.

Always following a heavy storm or extreme weather condition an inspection should be done and as shown in the table below.

| WEEKS | Building Roof | Light Duty Tower | Heavy Duty Tower |

| 13 |  |

||

| 26 |  |

|

|

| 39 |  |

||

| 52 |  |

|

|

LEGAL ADVICE

We sell this equipment to professionals and organizations in good faith it will be used correctly and legally. Nearly every country in the world require licensing for this type of equipment. It is the customer's responsibility to check relevant laws, directives, regulations and licensing requirements before installing or putting this product into service with an antenna system. You, the customer or user agree to defend, indemnify and hold harmless Aareff Systems Limited, it's employees and agents, from and against any claims, actions or demands, including without limitation legal and accounting fees, alleging or resulting from improper or unlawful use of this equipment.

© 2023 AAREFF SYSTEMS LIMITED

ALL RIGHTS RESERVED. Aareff is a trademark of Aareff Transmission Systems. All contents of this document including, but not limited to the images, logos, text, illustrations are protected by copyrights, trademarks and other intellectual property rights which are owned and controlled by Aareff Transmission Systems or by other parties that have licensed their material to Aareff Transmission Systems. This document in part or whole may not be copied, reproduced, republished, uploaded, posted or distributed in any way, including by e-mail, ftp or any other electronic means

Every care has been taken in the preparation of this document, errors in content, typographical or otherwise, may have occurred. If you have comments concerning its accuracy, please contact Aareff Systems Limited (UK)

+1 829 698 0733

What Do You Need? Talk To Us

+1 829 698 0733

What Do You Need? Talk To Us